Parler

Parler Gab

Gab

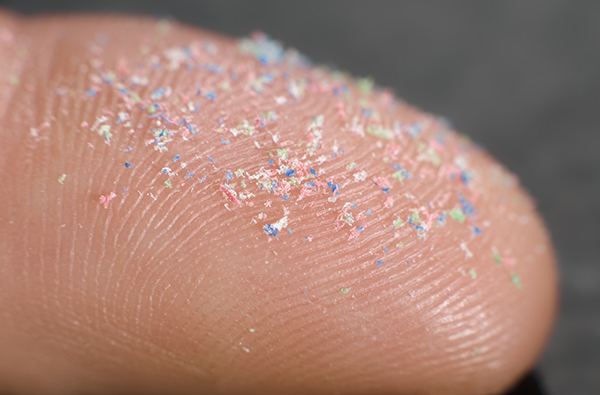

A new dawn in the battle against 'Forever Chemicals'

In a world increasingly plagued by the pervasive presence of per- and polyfluoroalkyl substances (PFAS), commonly known as "forever chemicals," a team of researchers at Rice University has unveiled a revolutionary method to tackle this environmental menace. Published in the journal Nature Water on March 31, the study demonstrates a novel approach that not only eliminates PFAS from water systems but also transforms waste into valuable graphene, offering a sustainable and economically viable solution to a problem that has long eluded effective remediation. PFAS, a group of synthetic compounds valued for their heat, water, and oil resistance, have infiltrated freshwater systems worldwide, posing significant health risks, including cancer and immune system disruptions. Traditional methods of PFAS disposal, such as incineration and landfilling, are costly, energy-intensive, and often generate secondary pollutants, exacerbating the environmental burden.Flash Joule Heating: a game-changing solution

The Rice University research team, led by James Tour, the T.T. and W.F. Chao Professor of Chemistry and professor of materials science and nano-engineering, and graduate student Phelecia Scotland, employed flash joule heating (FJH) to address these challenges. By combining granular activated carbon (GAC) saturated with PFAS and mineralizing agents like sodium or calcium salts, the researchers applied a high voltage to generate temperatures exceeding 3,000 degrees Celsius in under one second. Key findings:- The intense heat breaks down the strong carbon-fluorine bonds in PFAS, converting them into inert, nontoxic fluoride salts.

- The process achieves more than 96% defluorination efficiency and 99.98% removal of perfluorooctanoic acid (PFOA), one of the most common PFAS pollutants.

- Analytical tests confirmed that the reaction produced undetectable amounts of harmful volatile organic fluorides, a common byproduct of other PFAS treatments.

Transforming waste into a resource

Simultaneously, the spent carbon is upcycled into flash graphene, a high-value material used in industries ranging from electronics to construction. This dual-purpose approach not only eliminates hazardous chemicals but also transforms waste into a resource, offsetting treatment costs by US$60–100 per kg. The implications of this research extend beyond PFOA and perfluorooctane sulfonic acid (PFOS), the two most studied PFAS. The high temperatures achieved during FJH suggest that this method could degrade a wide range of PFAS compounds, paving the way for broader water treatment and waste management applications. As concerns over PFAS contamination continue to grow, this breakthrough offers hope for safeguarding water quality and protecting public health worldwide. Environmental and Economic Benefits:- The method is solvent- and catalyst-free, substantially reducing energy use, greenhouse gas emissions, and secondary waste.

- A techno-economic assessment highlights its scalability and environmental benefits, offering a rapid (~1 second), cost-effective solution for PFAS remediation.

Sustainable carbon-based solutions in Tokyo

In a parallel development, researchers at the Institute of Science Tokyo are exploring sustainable carbon-based materials and membrane distillation (MD) to remove PFAS from water. Led by Associate Professor Toshihiro Isobe from the Department of Materials Science and Associate Professor Manabu Fujii from the Department of Civil and Environmental Engineering, the team has developed a novel adsorbent and MD method to purify water contaminated with PFAS. The researchers utilized lignin, a byproduct of the pulp and paper industry, and glucose, a common sugar molecule, as carbon sources to develop their PFAS-removal technologies. The MD method, combining distillation and membrane separation, effectively rejects PFAS, allowing only water vapor to pass through the hydrophobic, porous carbon-based separation membrane. Experimental analysis showed that simulated contaminated water, containing PFOS at a concentration of around 500 ng/L, was reduced to around 3 ng/L after MD treatment, well below global environmental standards. The researchers also found that minimal amounts of activated carbon, treated with zinc chloride, could remove up to 99% of PFAS within 10 minutes. Isobe outlined plans to improve the MD purification method by switching to a solar heating method, aiming to develop an electricity-free system that does not rely on heaters. As the world grapples with the challenges posed by PFAS contamination, these innovative approaches offer a glimmer of hope. The Rice University and Tokyo Institute of Science studies highlight the potential of cutting-edge technologies to transform waste into valuable resources and purify water sustainably. Sources include: ScienceDaily.com Nature.com ScienceDaily.comRed Clover: A versatile healing plant with many health benefits

By Ava Grace // Share

HHS Secretary Robert F. Kennedy Jr. to end fluoridation of U.S. drinking water

By Laura Harris // Share

Governments continue to obscure COVID-19 vaccine data amid rising concerns over excess deaths

By patricklewis // Share

Tech giant Microsoft backs EXTINCTION with its support of carbon capture programs

By ramontomeydw // Share

Germany to resume arms exports to Israel despite repeated ceasefire violations

By isabelle // Share